Why use monocrystalline solar panels?

info

Why monocrystalline is the most preferred material for solar panels?

Sun light is one of the most powerful renewable energy sources out there that offer us a great chance to save our planet without sacrificing our electricity power needs. Wiuth the development of solar panel technologies we start to discover the plenty opportunities for putting sun’s energy into use. If our goal is to catch as much of sun’s enormous energy as possible at a spot of small size then monocrystalline is definitely the way to go.

Monocrystalline is a well-researched material since it exists on the solar market for a long time. Its technology has had a plenty of chance to develop so far and result in a reliable solar panel material. It’s in fact the oldest form of solar panel.

The first introduction of monocrystalline into the market was in the 50s while polycrystalline appeared for the first time in the 80s which is the reason why monocrystalline gained so much popularity and respect over the years. But this material gained its fame for a reason.

Monocrystalline completely deserves its fame as it’s the most efficient solar panel on the market (10 to 15% more efficient than the other available solar panels on the market). While the other types of solar panels are being gradually improved and their efficiency gets better, monocrystalline still holds the top position in the list.

Monocrystalline wafers (also called single-crystal cells) have characteristic and easily recognizable form. They usually have roundly-shaped or cut out corners and their form is usually blue. The reason why monocrystalline solar panels have chopped off edges is because their silicon wafers are made from a solid monocrystalline ingot.

Let’s take a look first at how monocrystalline silicon panels are made?

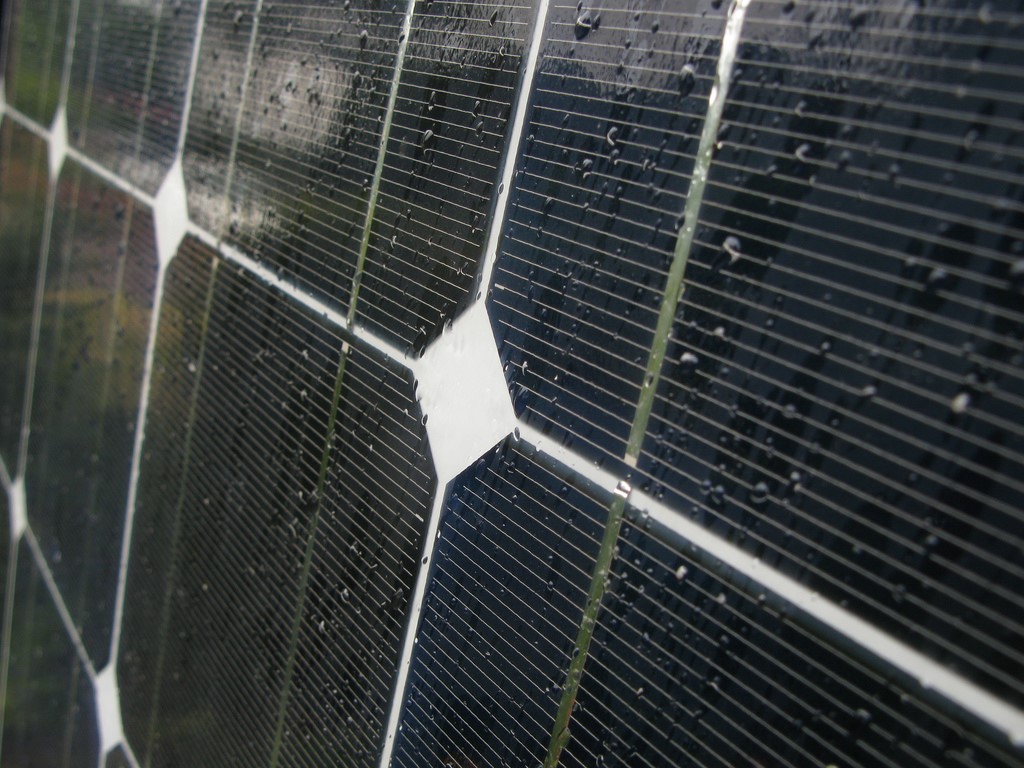

The name monocrystalline means “one crystal”. This is because monocrystalline solar panels are made from a single unbroken silicon crystal structure. This is one of the reasons why monocrystalline solar panels have uniform color. Monocrystalline solar panels are made from a single crystal ingot that has a cylindrical shape. With the help of a laser thin slices are cut from this silicon crystal cylinder.

These small silicon wafers are later additionaly shaped and installed on an aluminium frame which will be the future solar panel.

Monocrystalline solar panels are usually in uniform dark black color and have a characteristic square form which gives them a good aesthetic look. This square shape is achieved by cutting their corners in order to place more solar panels on a frame.

The cutting is performed by wire saws and they follow specifically set lines for cutting. Exactly for this reason monocrystalline is more costly to produce and creates more overall wasted silicon when compared to the other types of silicone solar panels like polycrystalline and thin-film panels.

This makes the material less friendly to the environment. Monocrystalline wafers are made by Czochralski process. It is named after a famous Polish scientist who discovered it unexpectedly and by fluke.

It includes placing silicon crystal seed into a vessel filled with molten silicon. After this the crystal seed is slowly extracted from the molten silicon. During this extraction process a solid crystal block is formed around this seed also called silicon ingot. In shape it is similar to a large cylinder. The four sides of this silicon block are finely sliced and what is left is formed into thin wafers which are used for making a solar cell.

Main reasons why we should choose monocrystalline

Effectiveness

Monocrystalline is the perfect material for our solar panel station since its highly productive and space efficient. Monocrystalline has the highest power yield. This great ability is thanks to the fact that monocrystalline is made from pure silicon of the highest possible quality.

Monocrystalline solar panels yield definitely more power from the sun when compared to the other solar panel types.

Excellent performance in bad weather

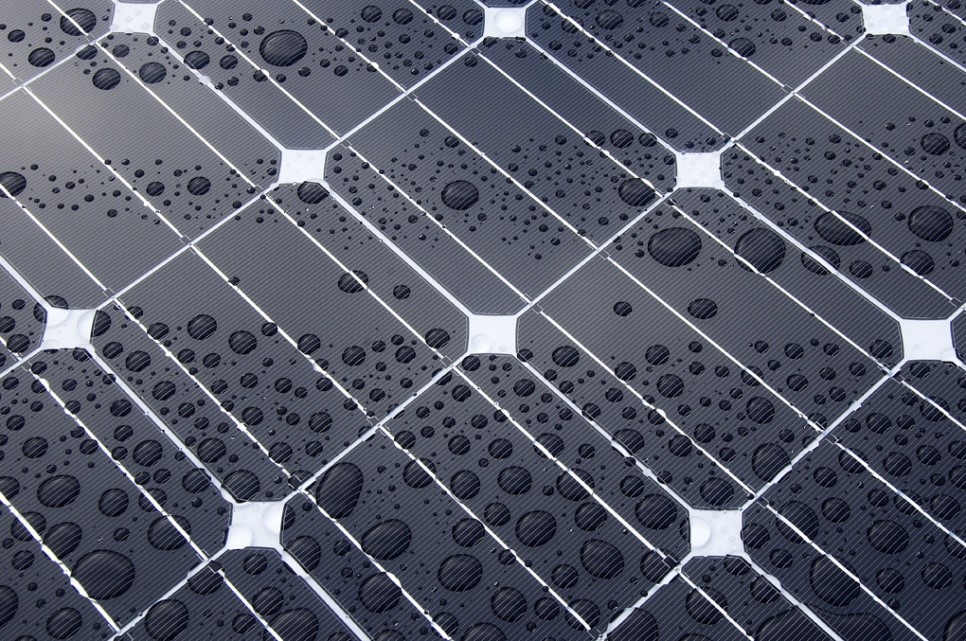

Monocrystalline proved itself to be the best material for solar panels when it comes to productiveness. Thanks to the extremely pure silicon used in their production method, monocrystalline solar panels convert the sun’s energy into electricity the best even in sunless weather. If the weather is cloudy, you can still reap as much sun power as possible if you have monocrystalline solar panels installed.

Another fact about monocrystalline is that it has better performance in bad weather conditions such as lack of sufficient sun light. This type of solar panel has better performance in shady conditions when the sunlight doesn’t reach the panel directly.

It also has high heat tolerance. It performs better in high temperature environment in comparison to the other types of solar panels.

It’s well-known that all kinds of solar panels don’t perform well when the weather becomes hot and experience efficiency loss in one way or another. This is true especially for hot ambient temperatures.

But in the case of monocrystalline solar panels this fall in productiveness is just insignificant in comparison to the energy loss of the other solar panel types like polycrystalline and thin-film solar panels. This high temperature resistance is once again achieved thanks to the fact that silicon of purest form is used in moncrystalline solar panels.

Life length and climate durability

Monocrystalline solar panels have a life span of at least 25 years which means sooner or later we will return our investment. An evidence for this fact is that some solar panels that still function now were actually installed in 1970.

Space efficient

You are space constrained for installing solar panels? Don’t worry because with monocrystalline solar panels at less space you can reap as much amount of energy as with other kinds of solar panels. Monocrystalline solar cells are a perfect solution when we have a limited roof or ground space for our solar panel project or live in an urban area with limited roof top space.

Down sides of monocrystlline:

Cost

One of the bad sides of monocrystalline solar panels is that their production process is way more expensive than this of the other types of solar panels. The process of silicon mold casting and shaping the wafers requires more resources, labor and proper care.

Monocrystalline production is 20% more expensive than making polycrystalline or thin-film solar structures. We need to invest more money upfront for a high quality technology. But the good news is that the considerable price we pay now will be refunded after a couple of years so it’s totally worth it.

Production time

Besides its high price and necessary production resources manufacturing monocrystalline requires also more time.

Fragility

Monocrystalline solar panels may have a long life, but they can be easily broken or damaged if a heavy object hits the frame. Moreover, the solar panels’ circuit can fail if they are covered by dirt, snow or there is some shade. And therefore the overall efficiency may decrease.

Despite its disadvantages like high price and a tendency for brittleness , monocrystalline’s good sides outweigh the bad ones.So in general this material provides us with many benefits compared to the other choices of solar panels. No matter how much is our budget we should consider making an investment in monocrystalline solar panels since it’s really worth it and we will certainly make a profit from it in the long run.